- BELLINI VANNE O ROSA FORTUNATA PDF FREE PRO

- BELLINI VANNE O ROSA FORTUNATA PDF FREE CODE

- BELLINI VANNE O ROSA FORTUNATA PDF FREE PLUS

- BELLINI VANNE O ROSA FORTUNATA PDF FREE DOWNLOAD

BELLINI VANNE O ROSA FORTUNATA PDF FREE DOWNLOAD

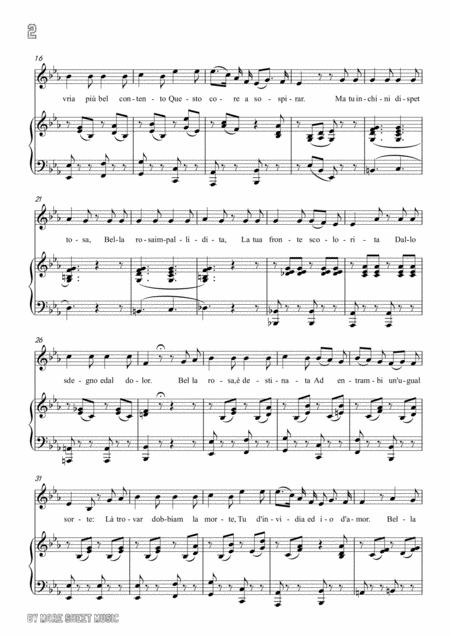

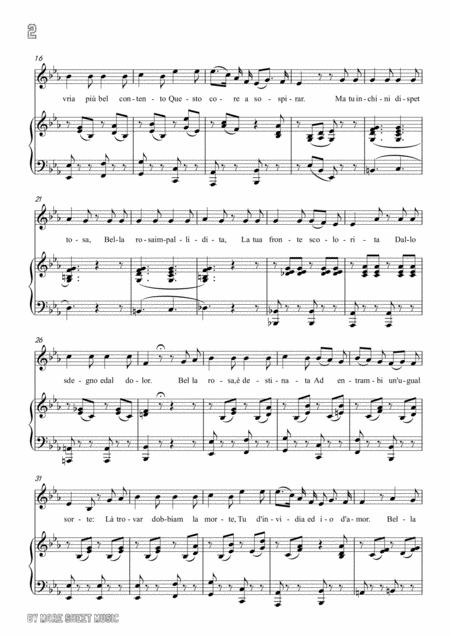

Piano, Vocal, Voice - Digital Download Composed by Vincenzo Bellini (1801-1835).

BELLINI VANNE O ROSA FORTUNATA PDF FREE PLUS

Sheet Music Plus reserves the right to cancel or change this offer at any time.Offer ends at 11:59pm PDT on October 27, 2022.The minimum order size is calculated in USD.Taxes and shipping are not included when determining the minimum order size.

BELLINI VANNE O ROSA FORTUNATA PDF FREE PRO

Does not apply to the purchase of Gift Certificates, hymnals, showkits, or products from these manufacturers: Acoustica, AirTurn, Alpine Hearing Protection, Antares, Apogee, Aquarius, Audient, Augustine Guitar Strings, Avid, Axe Heaven, Band Industries, Blue Microphones, ChordBuddy, Cloud Microphones, Cordial Cables, Danelectro, Flight, G7th, Gator Cases, GeerFab Acoustics, Gibraltar, Gretsch Drums, Griffin Technology, Grundorf, Hamilton Stands, Hartke Equipment, iConnectivity, IK Multimedia, iZotope, KAT Percussion, Korg, Levy's Leathers, Line 6, Loog Guitars, Michael Kelly Guitar Co., Mighty Bright, Morley Pedals, MXL, NMR Distribution, PG Music, PreSonus, Pro Tools, Propellerhead, Red Panda, Samson Audio, Singer's Mask, Singular Sound, Snark Tuners, Solomon Mics, Sonuus, Summit Audio, TASCAM, Vater Percussion, Vertex Effects, Warm Audio, and Woodrow. Coupon and gift certificate cannot be used on the same order. Only one coupon may be applied per order. Cannot be applied to previous or pending purchases. BELLINI VANNE O ROSA FORTUNATA PDF FREE CODE

Customer must enter coupon code during Checkout to receive discount. You are not required to create an account. A valid email address must be provided during the checkout process in order to receive a $5 coupon. Emails containing a $5 coupon code will be sent to eligible customers on or before November 15, 2022. Each customer will earn and be sent only one $5 coupon code via e-mail to use on orders of $35 more. Orders must be placed by Octoat 11:59pm PDT to be eligible for this offer. Simply enter the code REPEAT in the Promo Code field on the shopping cart page and click Apply to receive your discount. Alternative solutions include either reducing the amounts of such additives or carefully managing the balance of positively and negatively charged additives to improve the retention of all of the polymeric materials on fiber surfaces.Get 20% off orders of $20 or more and receive a $5 coupon via email to use on orders of $35 or more on a future order! Water-soluble, high-molecular-mass polymers such as cationic starch and wet-strength resins can be expected to stabilize foam bubbles if the additives are used at levels beyond what can be efficiently retained on the fiber surfaces. Likely sources of surface active materials include deinking agents, black-liquor carryover (in unbleached kraft operations), excessive rosin soap size or saponified rosin acid emulsion size, and in the formulations of various wet-end additives, including some biocides. Surface active materials tend to stabilize foams by lowering the interfacial tension between water and air. Sometimes these factors can be minimized. These involve application of vacuum and some type of fluid motion to separate dissolved and entrained air from the water phase.Ī long-term answer to air problems in a paper mill also should include consideration of chemical factors that tend to stabilize foams. Many modern paper machines, especially those producing fine and specialty paper grades, contain deaerating equipment. It is important also to make sure that the showers within air-padded headboxes are working effectively.

Often the breakage of surface foam is promoted by spray showers. On a basic, traditional paper machine the main mechanism of air release is the coalescence, creaming, and breakage of bubbles in the white water tray and white water silo areas, just after the paper has been formed. Also it is important to realize that the paper machine environment contains all of the key elements needed to create foam - water, air, lots of agitation and splashing, and various substances that can act as stabilizers. Leaky seals on pumps are a leading cause of unnecessary air entrainment. Though our main concern in this website is in regards to chemical factors, it is important to consider mechanical factors that can be contributing to air problems.

0 kommentar(er)

0 kommentar(er)